I am trying to implement a PI controller in C that outputs / controls a PWM's duty cycle on a microcontroller. The duty cycle that I can write to the certain PWM control register is limited to 10bit (values 0 - 1023 correspond to 0% - 100% duty cycle). My controllers output "Stell", that should correspond to a duty cycle, exceeds this bit limit due to calculations of the controlled values. Here is a simplified version of my controller function that is called regularely with a base clock:

void controller(void)

{

int32_t stell_1, stell_2, stell;

int32_t Integral;

int16_t delta_e;

uint32_t DZSoll, DZIst;

uint16_t duty_cycle;

int32_t temp_duty_cycle;

//Error = Setpoint - actual_value

delta_e = DZSoll - DZIst;

//PI controller

stell_1 = delta_e * Kp;

Integral += delta_e;

stell_2 = Ki * Integral;

stell = stell_1 + stell_2;

//Max values

Max_S1 = Max_delta_e * Kp;

Max_S2 = (Max_delta_e + Integral) * Ki;

Max_Stell = Max_S1 + Max_S2;

//Scaling of the controller output to a 10bit duty cycle

temp_duty_cycle = stell<<10; //*1023

duty_cycle = temp_duty_cycle / Max_Stell;

PWMUpdate(duty_cycle);

//...

}

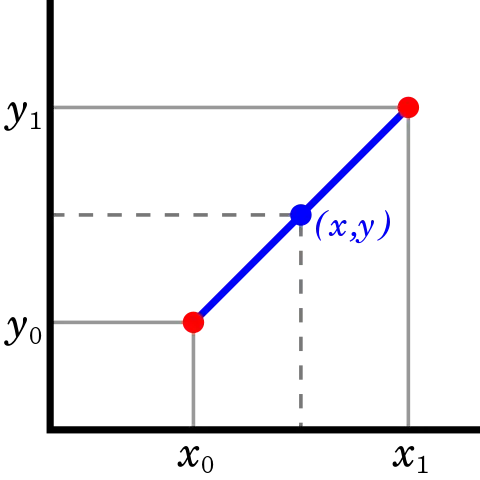

Now, I thought that I would need to scale the controller output "Stell" to the desired 10bit "duty cycle" by setting them into a relation: duty_cycle/2^10 = Stell/Max_Stell (basically to receive the scaling factor). Nevertheless, this only works for positive values of "stell" as my duty cycle by definition has to be a positive value (uint16_t). In the case that my actual value "DZIst" is bigger that the setpoint "DZSoll" (for instance on a overshoot of the integral part of the PI controller), this results in a negative "Stell" which is then incorrectly calculated into a duty cycle. This is especially a problem on lower setpoints as the Integral value cannot compensate the negative control error.

So, my question is: Am I scaling "Stell" correctly to the 10bit duty cycle? Could I compensate the negative "Stell" values with an offset (and how?)? I would appreciate every help a lot, thank you in advance!