The reason that the center surface cannot be built to be G3 to all 4 surfaces is because the 4 surfaces might not meet at the 4 corner points with G3 continuity. In fact, for the given condition that the curves 1/2/3, 4/5/6, 7/8/9, 10/11/12 are all G3 continuous only ensures that the 4 surfaces meet at the 4 corner points with G1 continuity.

The following is a bit more details per OP's request.

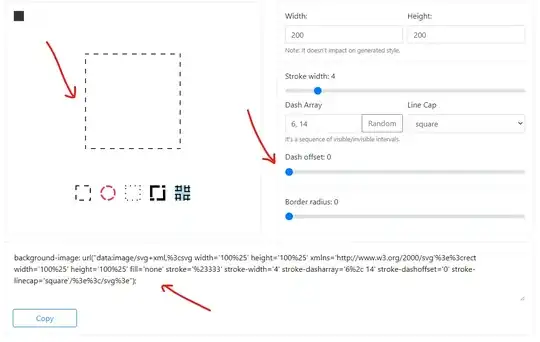

Let's denote two of the 4 surfaces as Surface A and B with coincident control points P and Q as shown in the following picture.

The normal vector of Surface A at point P is obtained by taking cross product of vector(P,P1) and vector(P,P2) and that for surface B at point Q is the cross product of vector(Q,Q1) and vector(Q,Q2). Since curve 1 and 2 are connected with G3 continuity, it means that vector(P,P1) is parallel to vector(Q,Q1). Similarly we have vector(P,P2) parallel to vector(Q,Q2). Therefore, we can conclude that surface A and B have the same unit normal vector at point P (or Q), which means the two surface meet with G1 continuity.

In order for surfaces A and B to meet with G2 at point P, 3 more control points from each surface will get involved (shown in the picture as green dots P3, P4 and P5 for surface A). All these 12 control points (6 from each surface) need to form a specific relationship in order for the two surfaces to meet with G2 continuity. The fact that curve 1/2 and 8/9 are connected with G3 continuity only affects the location of P3 and P5, and not the location of P4. Therefore, it does not ensure the two surfaces meet with G2 continuity at point A, let alone G3 continuity.