I am trying to generate a finite element mesh using PyGmsh, using the following code:

import pygmsh

geom = pygmsh.opencascade.Geometry(

characteristic_length_min=0.1,

characteristic_length_max=0.1,

)

rectangle = geom.add_rectangle([-1.0, -1.0, 0.0], 2.0, 2.0)

disk1 = geom.add_disk([-1.2, 0.0, 0.0], 0.5)

disk2 = geom.add_disk([+1.2, 0.0, 0.0], 0.5)

disk3 = geom.add_disk([0.0, -0.9, 0.0], 0.5)

disk4 = geom.add_disk([0.0, +0.9, 0.0], 0.5)

union = geom.boolean_union([rectangle, disk1, disk2])

diff = geom.boolean_difference([union], [disk3, disk4])

mesh = pygmsh.generate_mesh(geom, dim=2)

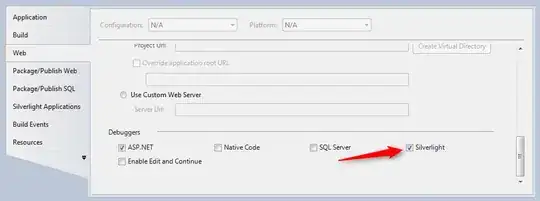

I can generate the following mesh:

However, I would like to add a crack to the mesh, something like:

The crack here is just an example, it would need to be defined before the meshing process.

I've tried creating 2 points (geom.add_point()) and a line (geom.add_line()), and then do a

geom.boolean_difference() between the final geometry and the line/crack, but this just does not work.

Any help would be greatly appreciated.

EDIT

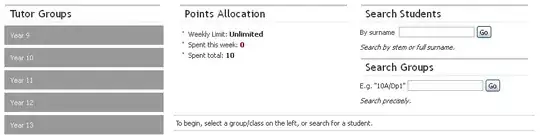

The purpose of this type of mesh generation is to simulate a physical crack in a body. In the meshing process, the crack can be modeled by the elemental connectivity of the mesh (i.e. the elements must have different nodes to create a crack face). Example, before applying any load, the crack is closed:

After applying the load, the crack opens since the element connectivity allows this: