This is just a form of steel fibre reinforced concrete (SFRC) with twisted fibers. SFRC in general has been around since 1874. It's also been heavily research for at least 50 years (previous source and the last in this answer say this.)

Twisted fibers are slightly better than other kinds in some respects, but not by much. (There's no point in getting into details on this here.)

As for replacing rebar, a more introductory 2018 academic presentation, which is aware of twisted fibers (has photos among the showcased types), has these general points about SFRC in general:

- The addition of fibres enhances the structural performance of plain concrete (much higher fracture energy)

- Fibres reduce the crack spacing and crack width, thereby improving serviceability and durability

- Currently used SFRC mixes exhibit a softening behaviour in tension and cannot fully replace conventional reinforcement

- Hybrid reinforcement (fibres and conventional reinforcing bars) can be used, but may affect ductility

So, SFRC is clearly not a replacement for rebar in general. And these bits are also relevant:

Several causes are preventing a more widespread use of SFRC:

Lack of standardised design procedures and material test procedures

High fibre contents (e.g. 1.5% = 120 kg/m3) as required for structural applications (and used in many experiments) are causing severe problems in terms of mixing and workability of concrete mix

With common fibre contents (e.g. 0.5% = 40 kg/m3), the tensile strength of concrete cannot be matched at cracking

Since this is written by a (Swiss) professor (ETH Zürich) in this field, I'd be amazed if he hadn't hear of some amazing breakthrough in this respect (in particular for products already commercialized.)

And if that's not enough, he repeats again:

For general application in engineering practice, it is necessary to

include conventional reinforcement in combination with SFRC to

ensure structural safety and an adequate crack distribution.

As for the table in Dave's answer, which is for a certain application (footings) it comes with this preamble:

For residential footings the International Residential Code (IRC-2015) section R403 describes the use of plain concrete

footings provided that the concrete will be in compression. However, it is customary to provide reinforcement to

minimize cracking and hold tight any cracks that occur due to drying shrinkage and/or differential temperature effects.

It's only in this optional role that they provide a replacement table. This actually not too surprising. The ETH presentation does mention (and has some pictures) of bridge deck overlays done with SFRC variants; it has a photo (and schematic) example of the Viaduc de Chillon (a bridge in Switzerland).

The same presentation does have one example of "more structural" SFRC-based bridge girders from Dura (a Malaysian company). These do indeed do away with most conventional reinforcements, according to the manufacturer:

DURA® UBG eliminate the used of conventional steel reinforcing bars and stirrups, except at regions where jointing detail are required for composite construction. All steel fibers used are made from high carbon steel wires with tensile strength of minimum 2300 MPa.

Due to the absence of conventional steel reinforcements, DURA® girders can be designed and produced in much slenderer and efficient sections, with no concern for classical issues such as minimum concrete cover, to prevent corrosion of steel reinforcement;

And they have been used in practice:

3rd December 2010 marks the history calendar of engineering in Malaysia as it is the date of the launching of Malaysia’s first ever Ultra-High Performance ‘ductile’ Concrete (UHPdC) bridge girder. This record breaking 50 m single span motorway bridge girder produced and designed by Dura Technology S/B and Perunding Faisal, Abraham dan Augustin S/B holds the marvel of engineering. To date, this bridge girder is considered as the world longest single-span prestressed UHPdC bridge girder for motorway application. The previous record was at 48 m in Japan.

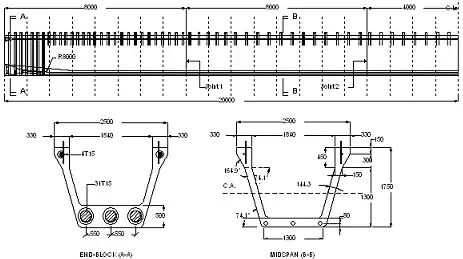

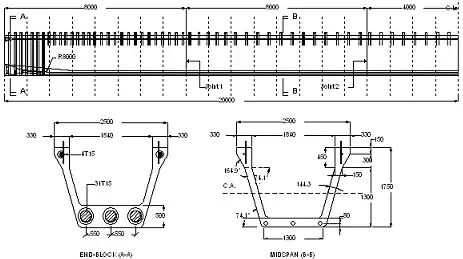

The girders look like this:

(The rebar sticking out is for the aforementioned "jointing detail".)

They have a schematic where this joniting rebar is present and where not (alas it's low resolution):