It depends on what spider you are measuring, what sort of silk from that spider, and what properties you want to measure.

The toughness of forcibly silked fibers averages 350 MJ/m3, with some samples reaching 520 MJ/m3. Thus, C. darwini silk is more than twice tougher than any previously described silk, and over 10 times better than Kevlar®.

[...]

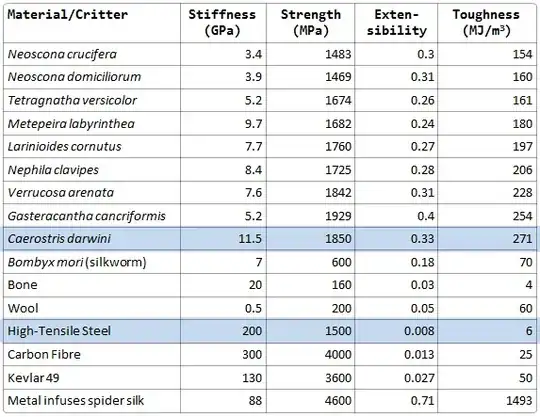

Caerostris darwini major ampullate silk is, on average, about twice as tough as typical silks spun by other orbweavers (Figs 3–4, Table 1, Table S1). Spider dragline silk is already deservedly renowned for its high toughness of ∼150 MJm∧-3, which outperforms both steel and Kevlar [32]. Yet, C. darwini silk is far higher performing, absorbing about ten times more kinetic energy before fracturing than does Kevlar.

Wikipedia covers many different mechanical properties of spider silk, including strength (same as some steels, less than Kevlar), strength per weight (where it beats steel and Kevlar), ductility and toughness. This may help you understand how silk beats Kevlar in some measures but not others.