By using a dehuller machine. See:

http://www.youtube.com/watch?v=-hegzzj9Rzk

or

http://www.buhlergroup.com/global/en/products/dehuller-dgba.htm

How does a dehuller work? I don't know, but it seems that Google does:

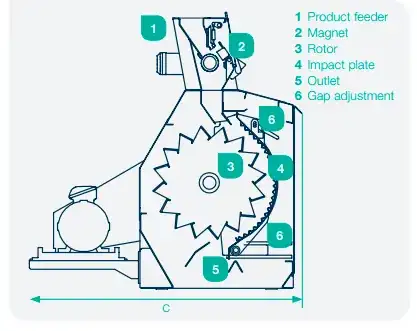

The most popular decorticator for sunflower is proposed by the Bühler

Cie. It consists in a rotating blade that propels the seeds by

centrifuge force against a wall. It functions on one impact. It is

designed for partial removal of hulls because due to its principle, it

is not able to carry out a good dehulling without increasing the force

of the impact. The kernel oil content is so high in sunflower that

under the violence of he chock, some oil can be transferred to the

hulls and is lost. Moreover, increasing the rotating speed of such

dehuller drives to increase the production of fines that are difficult

to separates from hulls. Another mono-chock kind of dehuller is

air-jet impact where the propelling of the seeds is done by a strong

current of air. Multi-chocks dehullers like the Ripple mill improve

the dehulling quality because they carry out several impacts on the

achene with milder violence and enable en enhanced separation of hulls

without generating an excess of fines.

See: http://www.creol.fr/CTMSite/creol/us/travaux/img/dehulling_3.pdf

See also: http://www.buhlergroup.com/northamerica/downloads/DGBA_Sunflower_Dehuller.pdf for some schematics of the inside of the machine and some insights about the way it works.