So I've bought a gas-powered pizza oven reminiscent of the Ooni Koda 12. It gets the crust done alright, but as I expected earlier it is quite difficult to rotate the dough using a peel without ending up with some parts burned and without an overall unevenness of baking level.

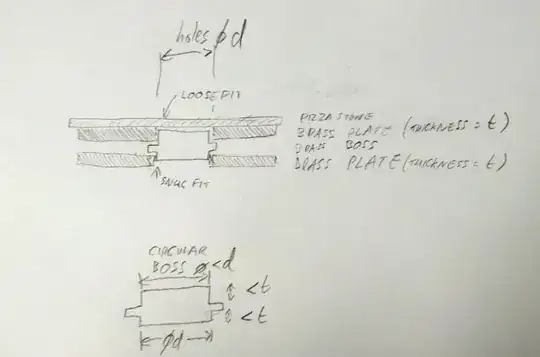

I've looked anywhere but couldn't find enough information on how to construct a (non-motorized) rotation mechanism into a pizza stone which could healthily withstand temperatures of 500 Celsius and perhaps a bit more.

Possible issues I suspect: pizza stones are cordierite — I don't think it can hold screws; so you consider gluing — is there any chemical glue which doesn't release toxic fumes at such degrees? And then considering the types of bearings available — most don't mention it but aren't they likely oiled with stuff that, again, might prove unhealthy within a gas oven?

I suppose this question isn't exactly food related, but I haven't found a definite SE category for this.